Principle and application of uvled curing oven

The uvled curing technology continues to mature, and more and more uv curing equipment and suppliers appear on the market. Let's share the principle and application of uvled curing furnace, and recommend reliable suppliers for everyone.

The uvled curing furnace is a curing equipment that uses ultraviolet light-emitting diodes as a light source, and is mainly used for curing UV glue, paint, ink, etc. The principle is to stimulate the photoinitiator in UV glue, paint, ink and other materials through the ultraviolet radiation emitted by UV LED ultraviolet light-emitting diodes, so that it can generate free radicals or cations, thereby initiating a polymerization reaction and forming a curing agent in a very short time. A polymer with a three-dimensional network structure.

uvled curing furnaces are widely used in many fields such as electronics, optoelectronics, furniture, building materials, printing, packaging, etc., especially in occasions that require high efficiency, environmental protection, and energy saving, such as large-scale production lines, automobile manufacturing, electronic assembly, optical component manufacturing, etc., uvled curing Furnace has become an indispensable important equipment.

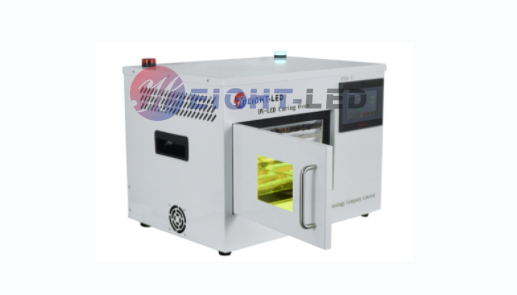

Taking Height-LED uvled curing furnace as an example, it is widely used in optical communications, wafers, medical consumables, 3D printing, cameras, electroacoustics and other fields, serving thousands of customers at home and abroad, and has won unanimous trust and praise from customers.

Height-LED uvled curing furnace adopts lamp beads imported from Seoul, South Korea, with high luminous efficiency, long life, good stability, and environmental protection; it is also equipped with intelligent safety door protection, production technology statistics, light source high-temperature alarm, digital dimming, formula data and data Storage and other functions can effectively help enterprises improve production efficiency and ensure product quality.

Height-LED uvled curing oven is made of iron and white paint, with a beautiful and elegant appearance. The alarm buzzer helps to regulate the use of equipment, configure air-cooled or water-cooled heat dissipation methods, and ensure the safety of life and property. Automatic mode and manual mode are optional, and the surrounding area of the acrylic plate is anti-light leakage, suitable for a variety of application scenarios. The cold light source can be used for curing a variety of heat-sensitive materials, and it is convenient and efficient to clean dust in daily maintenance.

Height-LED uvled curing furnaces can be customized in terms of external dimensions, inner cavity dimensions, wavelength, power, etc., to effectively meet the diverse, diverse and individual needs of customers. If you want to know more uvled curing case information or have related needs, please contact us.