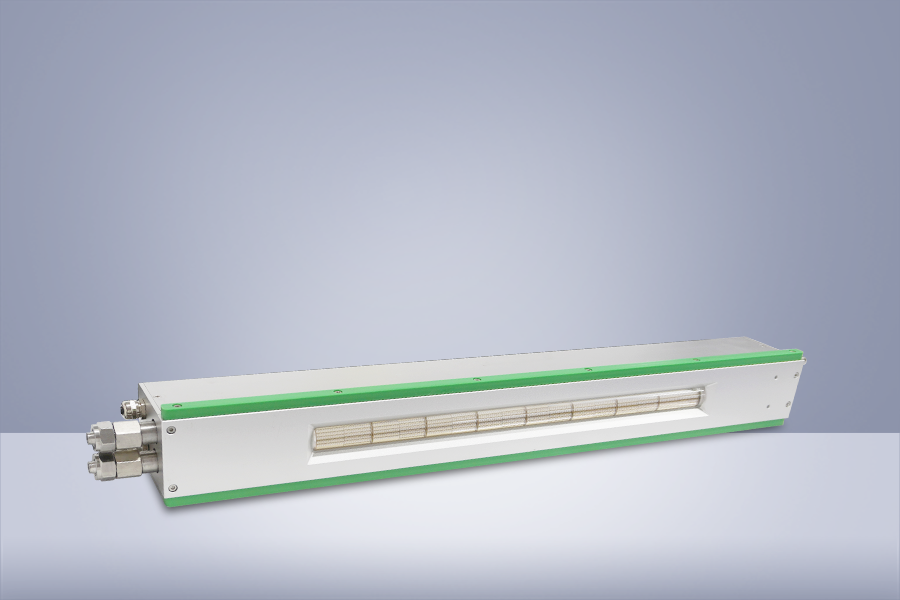

During the mass manufacture of pre-print liners and labels, flexible package, plastic and paper bags/cups, pre-print carton, heavy-duty paper sacks…, flexo printing plays an important role. And UV LED curing systems have made deep inroads into a variety of flexo label converting processes; compared with medium pressure mercury arc lamps, the major process benefits of LED-UV curing can be summarized by the following points:

- The quicker turnaround time (Fast changeovers via curing adjustments (e.g. precise and quick adjustments of working distance, wavelengths, and UV energy output) and flexible controls are more feasible with LED-UV curing);

- Easier to retrofit.

- Safer working environment.

- Reduced operating costs.

- More consistent printing results and improved process reliability.

- More press uptime due to its significantly longer working life (It is no exaggeration to say that LED-UV curing systems can operate up to more than 10 times longer than mercury arc UV curing systems).

For those new users who switch from conventional UV flexo inks to LED-UV flexo inks, they can experience a significant increase in the production speed compared to their experience of using traditional UV curing technologies.