What is UVLED screen printing light source and what are its uses

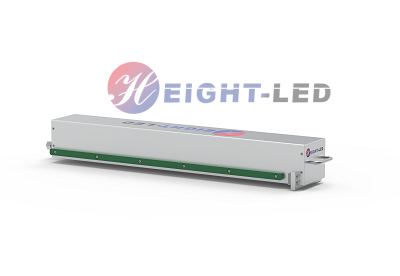

What is UVLED screen printing light source

A UVLED screen printing light source is a type of light-emitting diode (LED) technology that emits ultraviolet (UV) light in the UV-A or UV-C spectrum. It is specifically designed for use in screen printing processes to cure or dry UV-curable inks, coatings, adhesives, and other materials. The UVLED light source replaces traditional UV lamps commonly used in screen printing with more energy-efficient and environmentally friendly alternatives.

UVLED screen printing light sources are integrated into screen printing machines and systems to expose printed materials to UV light for rapid curing. When UV-curable ink or coating is applied to a substrate through a stencil, the UVLED light source is activated, and the UV light interacts with photoinitiators present in the ink or coating. This interaction triggers a chemical reaction that causes the ink or coating to harden and solidify, instantly drying the printed material and making it ready for further processing.

Uses of UVLED screen printing light sources

Screen Printing: In the screen printing process, UVLED light sources are used to cure UV inks on various substrates, such as paper, plastics, glass, metal, and textiles. The UV ink is applied through a stencil onto the substrate, and then the UVLED light source is used to rapidly cure the ink, making the print instantly dry and ready for further processing.

3D Printing: In the context of 3D printing, some printers use UVLED light sources to cure photopolymer resins layer by layer, enabling the creation of solid objects.

Surface Coating: UVLED light sources are also used for curing UV coatings on surfaces to provide protection, enhance appearance, or improve durability.

Adhesive Bonding: UVLED light sources are employed in bonding applications where UV-curable adhesives are used. The light cures the adhesive, creating a strong and rapid bond between materials.

Electronics Manufacturing: UVLED light sources find applications in electronics manufacturing processes, such as curing adhesives, coatings, and solder masks.

Medical Applications: In the medical field, UVLED light sources are used for curing dental materials, bonding medical devices, and sterilizing surfaces and equipment.

Advantages of UVLED screen printing light sources:

Energy Efficiency: UVLEDs consume less energy than traditional UV lamps, reducing operating costs.

Longevity: UVLEDs have a longer lifespan compared to conventional UV lamps, resulting in reduced maintenance and replacement costs.

Instant On/Off: UVLEDs provide instant on/off capabilities, eliminating warm-up and cool-down times associated with traditional lamps.

Eco-Friendly: UVLEDs do not contain mercury and produce less heat, making them more environmentally friendly.

It's important to note that technology evolves rapidly, and advancements might have occurred since my last update.