What is uvled curing light source, what are the application fields

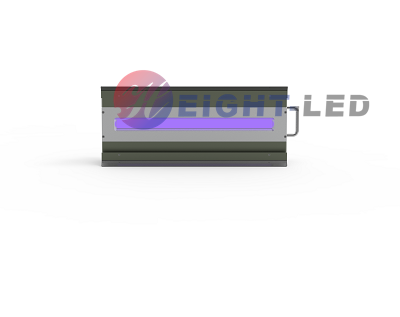

A UV-LED curing light source is a specific type of curing light that utilizes light-emitting diodes (LEDs) that emit ultraviolet (UV) light in the range of 365 to 405 nanometers. UV-LED curing lights are commonly used in various industries, including dentistry, manufacturing, printing, and electronics, where precise and rapid curing of UV-curable materials is required.

UV-LED curing lights find applications in several fields:

1.Dentistry: In dentistry, UV-LED curing lights are used to cure light-sensitive dental materials, such as dental composites, adhesives, and sealants. The ability to deliver precise wavelengths of UV light allows for controlled and efficient polymerization of these materials, leading to durable and strong dental restorations.

2.Printing and Coating: UV-LED curing technology is utilized in the printing and coating industry for curing UV inks, varnishes, and coatings on various substrates. UV-LED curing enables instant drying and hardening of inks and coatings, resulting in high-quality prints and finishes.

3.Electronics Manufacturing: UV-LED curing is employed in the production of electronic devices and components. It is used for the rapid curing of adhesives, encapsulants, and conformal coatings in the assembly and packaging of electronics. The precise control of UV light exposure ensures consistent results.

4.3D Printing and Additive Manufacturing: In the realm of 3D printing, UV-LED curing plays a crucial role in curing and solidifying UV-sensitive resins layer by layer. This technology is widely used in stereolithography (SLA) and digital light processing (DLP) 3D printers.

5.Adhesive Bonding: UV-LED curing is used in bonding applications where rapid and reliable curing of adhesives is essential. This includes industries such as automotive manufacturing, aerospace, and consumer electronics.

6.Wood and Furniture Industry: UV-LED curing finds applications in the wood and furniture industry for curing UV coatings and finishes on wooden surfaces. It enables quick curing without the need for lengthy drying times.

7.Medical Device Manufacturing: UV-LED curing is used in the assembly and production of medical devices, particularly for bonding and sealing applications in medical equipment and devices.

8.Optical Fiber and Cable Manufacturing: In the production of optical fibers and cables, UV-LED curing is utilized for curing protective coatings and adhesives, ensuring optical clarity and mechanical stability.

9.Cosmetics and Nail Art: UV-LED curing is employed in the beauty industry for quick and efficient curing of UV-curable nail polishes, gels, and other cosmetic products.

The advantages of UV-LED curing lights include energy efficiency, long operational lifespan, minimal heat generation, reduced environmental impact, and the ability to deliver specific wavelengths for optimized curing. These benefits have led to the widespread adoption of UV-LED curing technology in various industries where precise and fast curing of UV-sensitive materials is required.