The principle and application of uvled surface light source curing

Nowadays, the UV LED surface light source curing technology continues to develop and mature. The following introduces its curing principle and application. If you want to know more case information or have related needs, please contact Height-LED.

1. UV LED surface light source curing principle

UV LED light source curing technology is a curing technology based on ultraviolet light emitting diodes (UV LED). The principle of this technology is to use the ultraviolet radiation generated by UV LED to excite the photoinitiator in the liquid UV material to generate free radicals or cations. Thus triggering the polymer material (resin) containing active functional groups to polymerize into an insoluble and infusible solid coating film.

Specifically, UV LED light source curing is firstly that the ultraviolet radiation emitted by the UV LED is focused by the condenser lens to form a high-intensity ultraviolet beam; secondly, the ultraviolet radiation emitted by the UV LED is focused by the condenser lens to form a high-intensity ultraviolet beam. The ultraviolet beam; again, excited state free radicals or cations trigger the polymer material (resin) containing active functional groups to polymerize into an insoluble and infusible solid coating film; finally, under the continuous action of ultraviolet radiation, the polymer material is continuously cross-linked and polymerized , to form a three-dimensional network structure of high molecular polymer, to complete the curing process.

2. Application of UV LED surface light source curing equipment

UV LED surface light source curing equipment is widely used in various fields, such as printing, 3C, medical, furniture, construction, etc. In the printing field, UV LED surface light source curing equipment can be used to cure printing ink, glue, etc.; in the 3C field, UV LED surface light source curing equipment is mainly used to cure mobile phone casings, tablet computer casings, etc.; in the medical field, UV LED curing equipment It can be used for dispensing and pressing curing of medical equipment and medical consumables; in the field of furniture, UV LED surface light source curing equipment is mainly used for curing wood paint, furniture stickers, etc.; in the field of construction, UVLED surface light source curing equipment is mainly used for curing glass Curtain wall, floor paint, etc.

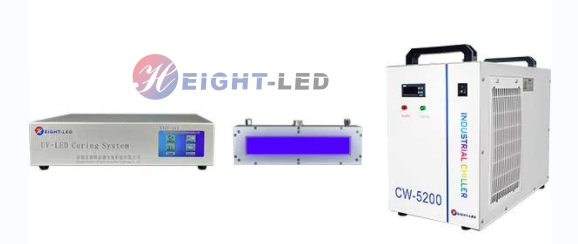

Height-LED is customer-oriented, and various parameters such as the light output area, wavelength, and power of UV LED surface light source curing equipment can be tailored to meet customer needs. Hetnyder UV LED curing equipment has been widely used in optical communications, laser semiconductors, cameras, medical consumables, touch screens, data wires, electroacoustics and other fields, and has won wide acclaim from customers.