Curing principle and application of uvled line light source

Traditional mercury lamps have problems such as short service life, high power consumption, high irradiation temperature, and harmful gases in the product. The uvled curing equipment effectively solves the above pain points and wins the trust of more and more customers. The following share the principle and application of uvled line light source curing, welcome to read.

1. The curing principle of uvled line light source

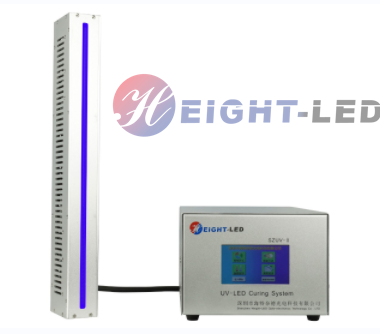

uvled line light source curing is a technology that uses ultraviolet radiation to cure. uvled line light source curing equipment is usually composed of uvled lamp beads, lenses, reflectors and other components, which can focus the ultraviolet light emitted by uvled lamp beads into a linear beam, through Control the irradiation time and intensity of ultraviolet light to achieve the curing of the material.

When the uvled line light source irradiates the surface of the material, the photoinitiator in the material is excited to generate free radicals and ions, and these free radicals and ions react with the molecules in the material, making the molecules cross-linked into a three-dimensional network structure, thereby forming a solid state.

The wavelength and energy of ultraviolet rays determine the speed and depth of curing. Different wavelengths and energy of ultraviolet rays are suitable for curing different types of materials.

2. Application of uvled line light source curing equipment

1. Electronic products: uvled line light source curing equipment can be used to cure printed circuit boards of electronic products.

2. Optical communication devices: uvled line light source curing equipment can be used to manufacture optical communication devices, such as optical fiber connectors, optical switches, optical sensors, etc.

3. Medical devices: uvled line light source curing equipment can be used to manufacture medical devices, such as cell factory assembly, bacteria collection cup dispensing and curing, catheter stent injection molding, capsule endoscope dispensing and curing, etc.

4. Coating and printing: uvled line light source curing equipment can be used in the coating and printing industry, such as offset printing, flexo printing, silk screen printing, etc.

5. Automobile manufacturing: uvled line light source curing equipment can be used to manufacture auto parts, such as car windshields, car lampshades, etc.

6. Plastic products: uvled line light source curing equipment can be used to manufacture plastic products, such as plastic bottles, plastic barrels, etc.

Height-LED has been focusing on the field of uvled curing for 12 years, and is committed to becoming a world-renowned supplier of uvled solutions and equipment to achieve a win-win situation with customers. Hite Ned imported brand lamp beads from Seoul, South Korea, with long service life, and the switch does not affect the life; the output band is concentrated, the photoelectric conversion rate is high, and the curing speed is fast; it can be turned on and off without preheating; the cold light source can be used for various heat-sensitive The solidification of materials meets the diverse, diverse and individual needs of customers; it is green and environmentally friendly, harmless to the human body and the environment......

Height-LED uvled line light source curing equipment has been widely used in optical communication, electronic products, printing, medical treatment, semiconductor and other industries, serving thousands of customers at home and abroad, and has won the unanimous trust of customers.